Injection: Intelligent, innovative

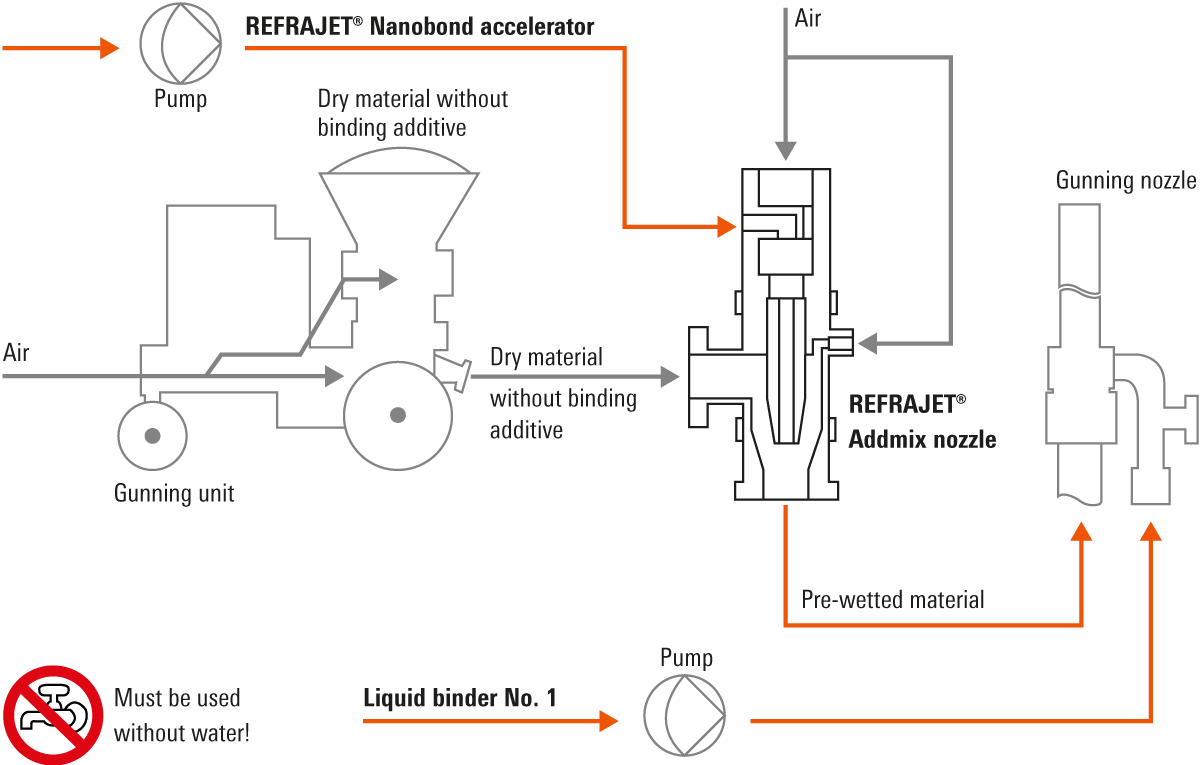

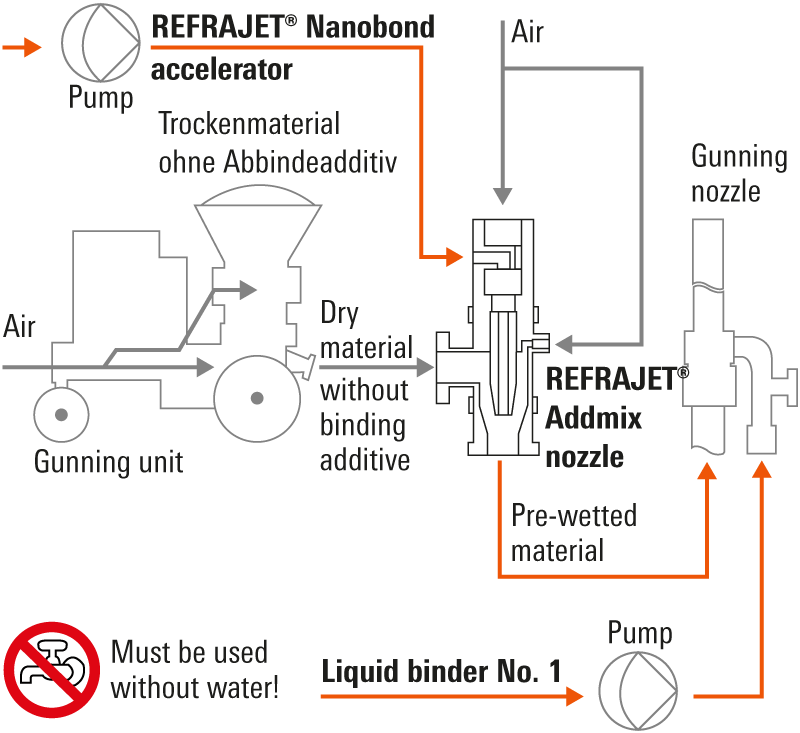

We have developed this innovative injection system specifically for our REFRAJET® Nanobond dry-gunning concretes. REFRAJET® Addmix reduces material rebound as well as dust generation at the injection nozzle.

As a result, you can count on improved mechanical properties and reduced porosity.

The material

- The dry material has a practically unlimited storage life and requires no special marking, as it is manufactured without chemical additives or binders.

- Bonding strength and layer thickness on refractory surfaces can be adjusted and varied without any problems.

- Product properties are significantly improved:

- onding on worn refractory surfaces is greatly improved.

- Pre-wetting the concrete results in a denser concrete struture with reduced porosity.

- Compared with the standard procedure, cold crushing strength and cold modulus of rupture can be increased significantly.

Processing

- Pre-wetting by means of a centrally injected aerosol greatly reduces the risk of hose blockages

- Dust generation is also reduced noticeably – particularly during overhead work

- Material rebound is also reduced clearly

- Fine particle activation is more intense than with the standard procedure

- The gunning operator is not hampered additionally: He simply works as accustomed with his standard equipment, because the injection parameters are adjusted by the injection machine operator via the system‘s control unit.

The REFRAJET® Addmix nozzle

- The nozzle can be used with practically every conventional rotor injection machine

- All parts of the REFRAJET® Addmix nozzle are easy to replace

- The injection of other liquids or powders is possible

- In order to reduce dust gene-ration and material rebound, REFRAJET® Addmix can also be used with hydraulically bonding refractory concretes