The new development: Hybrid technology

Hybrid technology permits the combination of faster heat-up and high strength at low temperatures. It is therefore ideally suited for applications in which high strengths are required in the range of 20…1000 °C; for example in the production of prefabricated components or the lining of fluidized bed furnaces and refuse incineration plants.

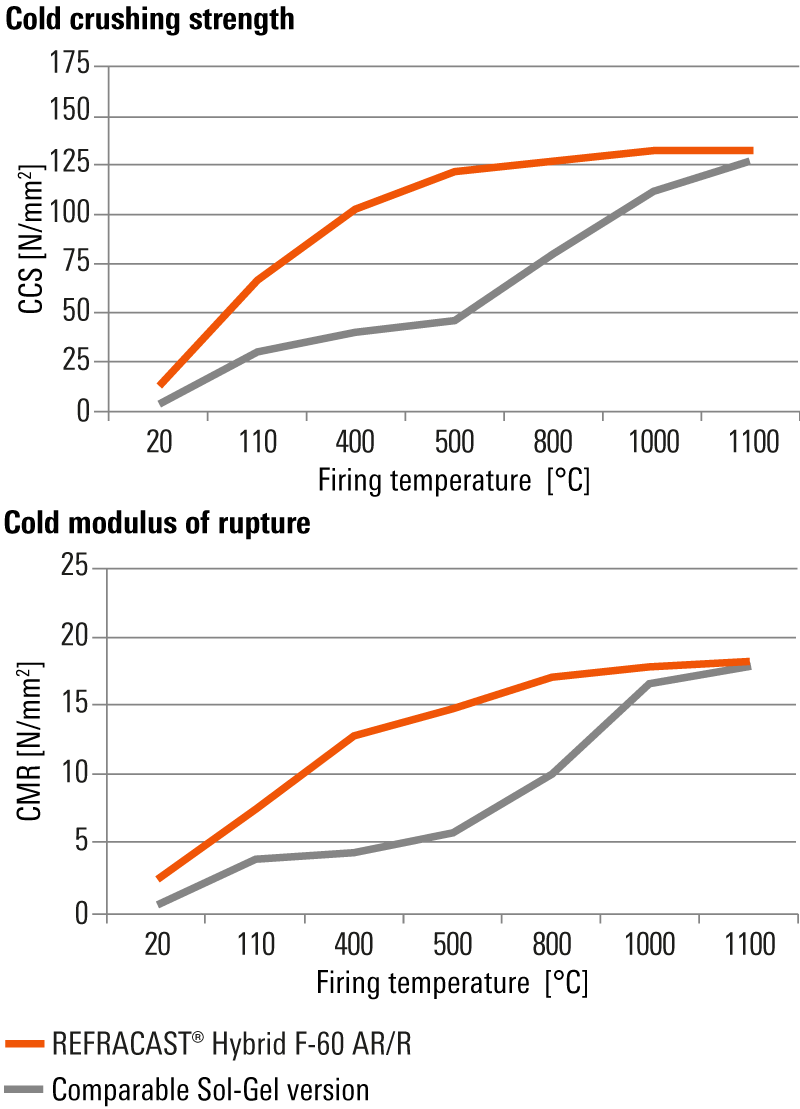

Advantageous

Strength comparisons of REFRACAST® Hybrid F-60 AR/R and a Sol-Gel bonded castable.

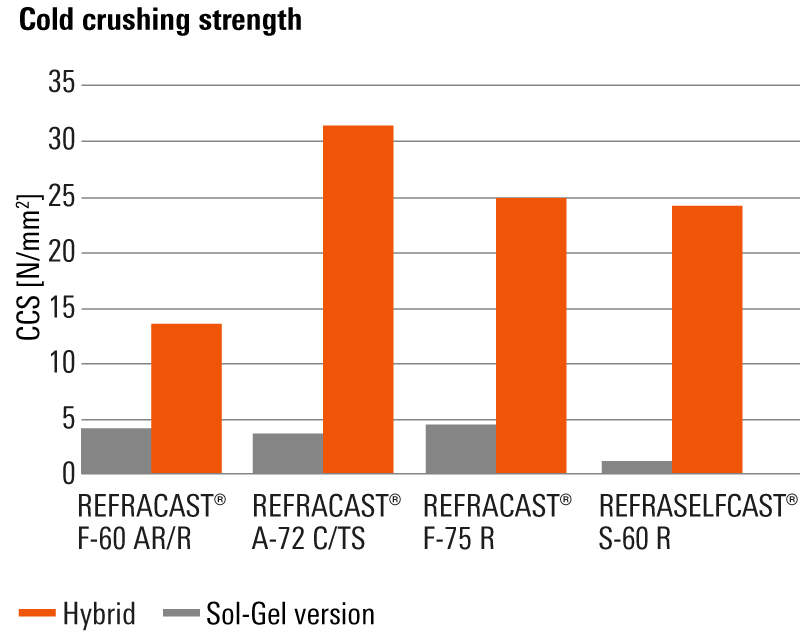

Clearly advantageous

Cold crushing strength of hybrid castables and Sol-Gel bonded castables at 20 °C/24 h; Hybrid castables exhibit a significant increase in cold crushing strength.

Hybrid castables make all the difference

compared with conventional cement containing castables:

- Faster heating up with shorter downtimes

- Cost and energy-saving

- Very good adherence to existing refractory materials

- Installation possible on hot surfaces and with high ambient temperatures

- Higher application temperature limits

- Optimized thermomechanical behaviour

- Long storage life of 12 months

- Increased cold crushing strength and modulus of rupture as well as optimized abrasion resistance in the temperature range below 1000 °C.