The end of the pitch era

Due to the characteristic polycyclic aromates, pitch is no longer tolerable in the steel industry.

The same applies for conventional phenol-based synthetic resin, because the carbon that is produced during coking does not become stiff and brittle, but is crystalline like graphite, so that the refractory material yields under stress, instead of compensating it with macro cracks.

The challenge

For Refratechnik Steel it was important to face the technical challenge and develop a process that combines the advantages of both bonding systems while eliminating their disadvantages.

With REFRAFLEX® we have been successful.

The solution:

REFRAFLEX® inside

Our bonding agent REFRAFLEX® is used in all of our MACARBON® bricks. Consequently, there is no longer any valid reason to continue using pitch-based or classic resin-based refractory materials.

A powerful bond

REFRAFLEX® offers decisive advantages compared to pitch-based bonds with their characteristic polycyclic aromates. But also when compared with conventional phenolic resin binders, REFRAFLEX® exhibits its capabilities:

The carbon generated during coking becomes neither rigid nor brittle.

No macro-cracks occur under excess loading, because the carbon from the bonding phase exhibits graphite-like properties already at very low application temperatures.

Decisive success factor

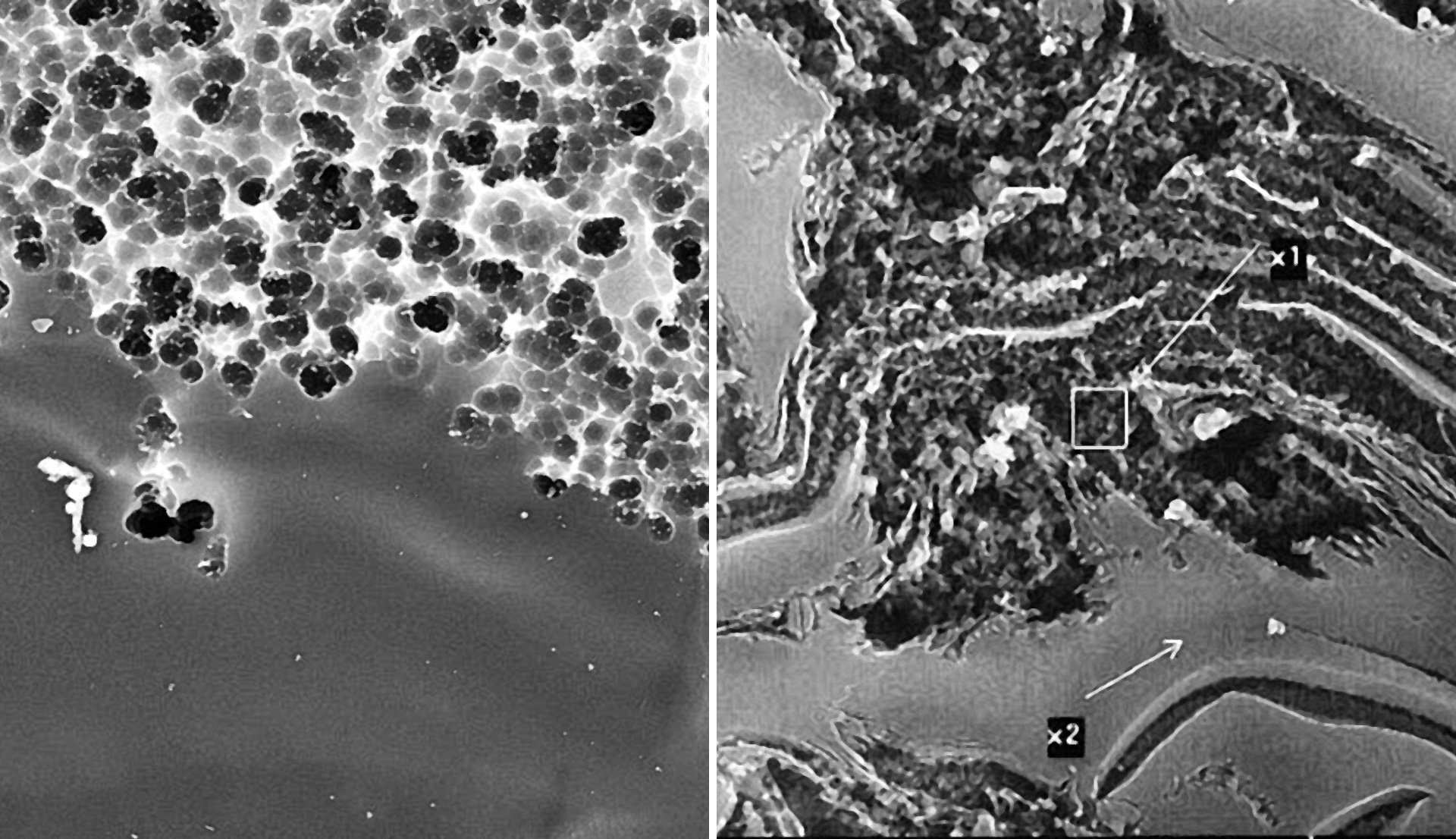

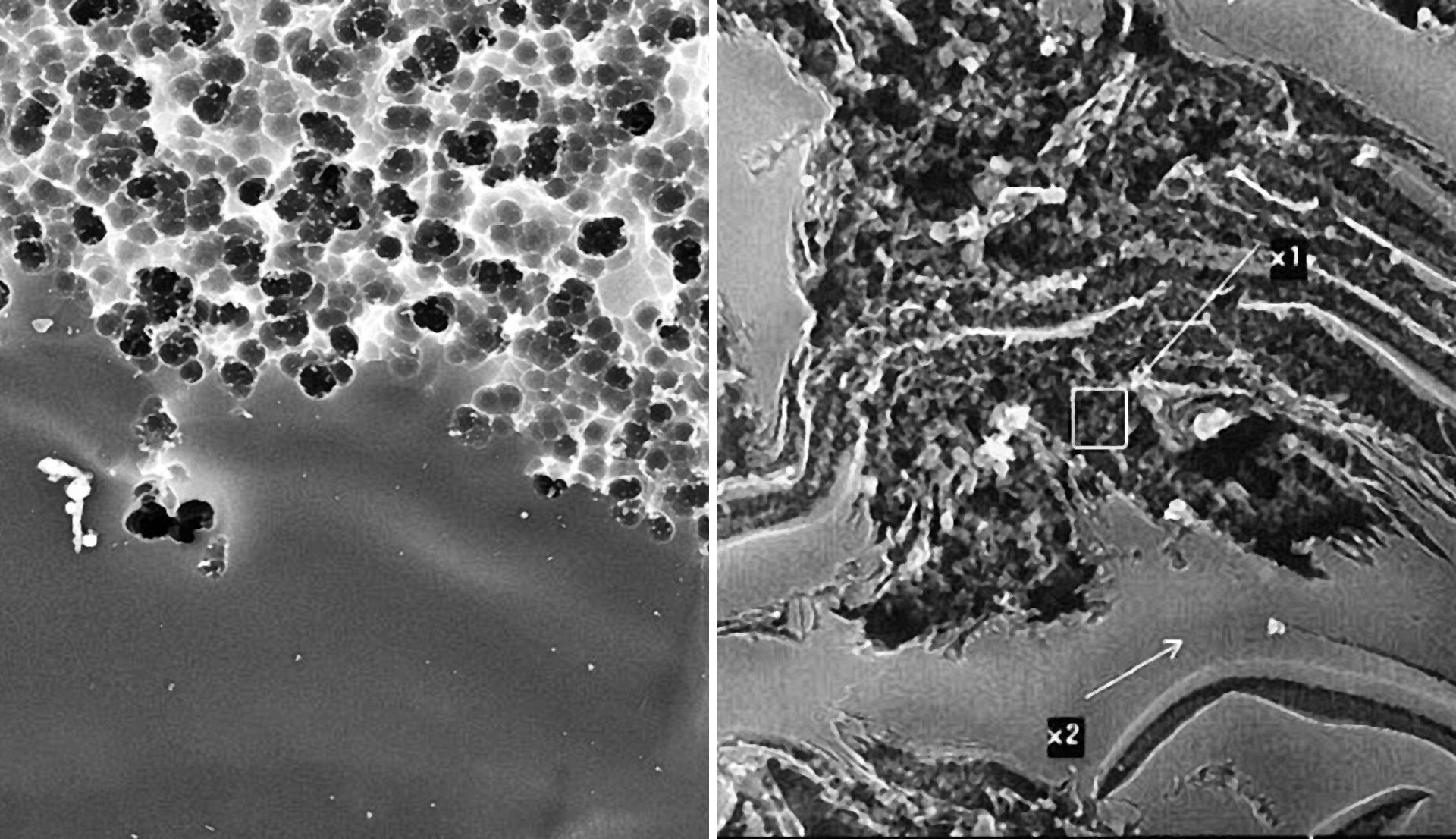

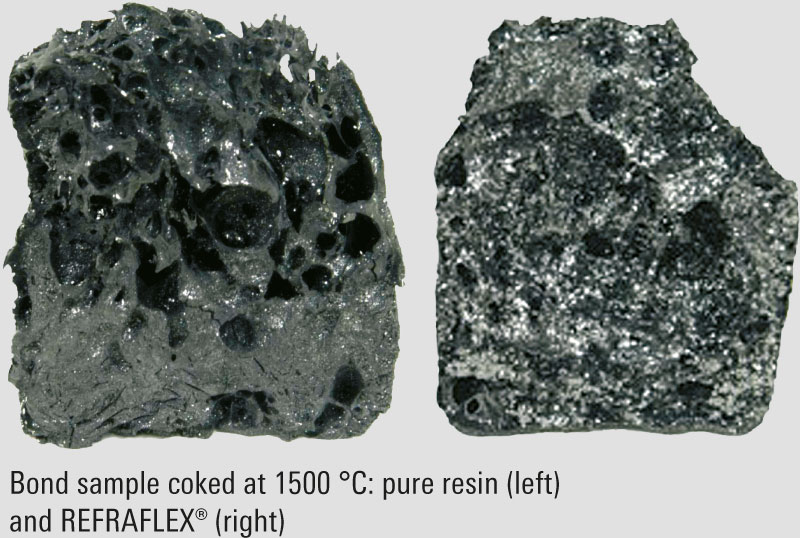

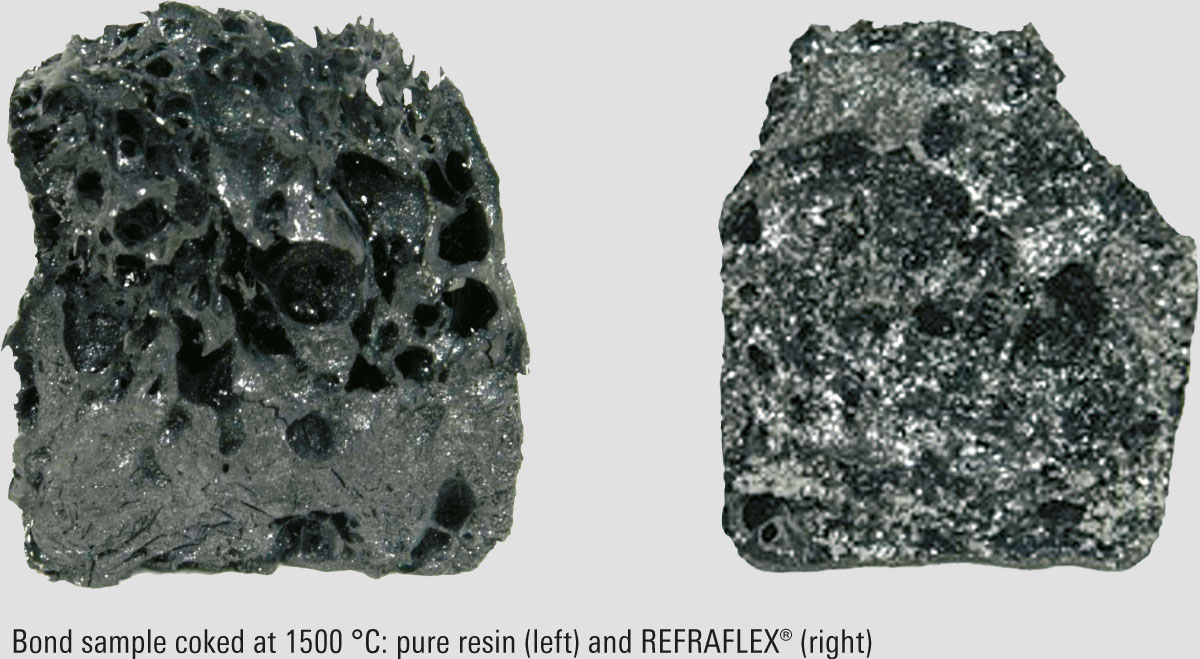

Through the heat treatment at 1500 °C spherical areas can be seen with the normal resin bonding next to amorphous phases, which indicate the beginning of the crystalization or vaporization processes. With the REFRAFLEX® bond on the other hand, these amorphous structures are no longer present. The lamellar layered structure of a well graphitized carbon is clearly visible, which makes the refractory brick so flexible that it does not crack from stresses.

(Figures: Left: Normal resin bonding, right: REFRAFLEX® bond)